What Type of Air Compressor is Right for Me?

For those already well-versed in construction and DIY, an air compressor may already be a part of daily life but for those who are just beginning to look at investing in one, it helps to know what to look for in an air compressor, and whether or not you are actually going to need one.

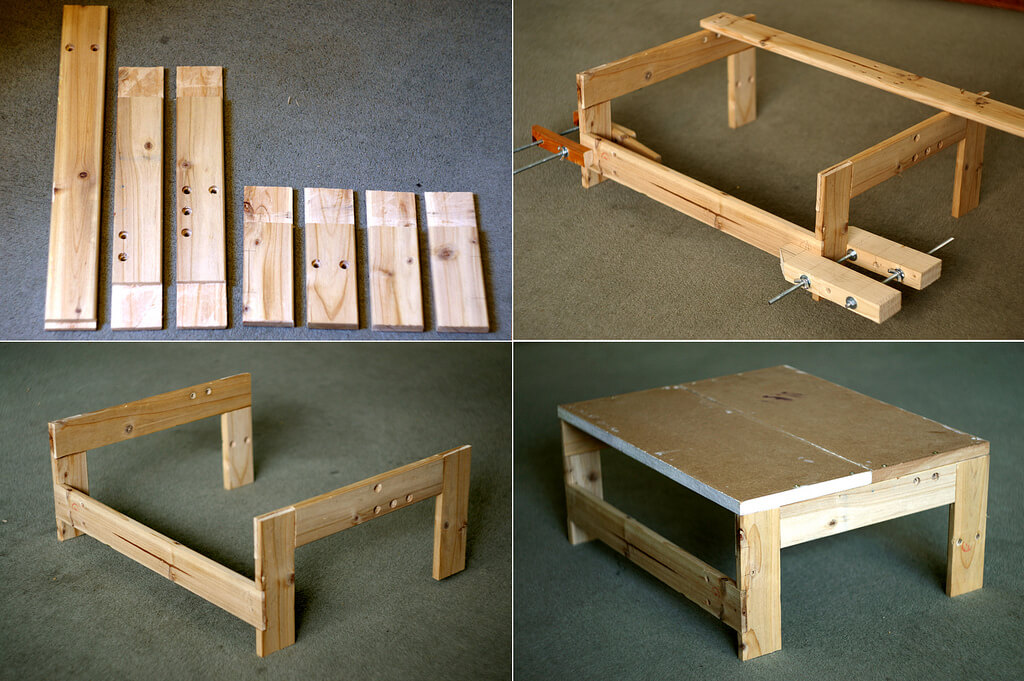

One of the most common reasons that folks will buy an air compressor, especially if they are in the construction field, is that they use it to operate a pneumatic nail gun. Battery-operated nail guns are becoming more popular because they are "wireless", though they tend to cost more and a battery charge generally doesn't last as long as air pressure. For reliability and to avoid spending an arm and a leg, many builders will stick with the pneumatic over the battery, meaning that an air compressor is required.

Perhaps more common, or at least just as common, is the air compressor that DIY junkies keep in the garage for automobile-related project. If you're changing out a fuel filter or installing a new PCV valve, for example, or even if you're just looking to keep your tire pressure consistent, air compressors will do the trick. Much like the pneumatic nail gun, other tools such as drills can be operated more reliably by switching to a pneumatic system. Pressure washers, sand blasters, air sanders, and air blow guns that clean loose sawdust and dirt off of situations all make use of an air compressor.

If you need to power one of these many pneumatic tools, then great--you now know you need an air compressor. The trick from here is to figure out what type you'll need by taking into careful consideration all of your needs.

First, how much space do you have? If you're living in a smaller unit, somewhere such as a condominium or a loft apartment without a garage, you might be looking at keeping a smaller, quieter pancake compressor, which can be stored in a closet or on a shelf.

Of course, you'll have to keep in mind that a smaller portable unit will be more limited than a full-size portable unit, due in part to its smaller tank size. Tank size is usually calculated in gallons, and will be critical when determining how your compressor will be used. If you're ejecting air in short blasts, such as with a pneumatic nailer, you might be able to get away with a smaller size. On the other hand, if you're using your air compressor for consistent pressure washing, you're probably not going to be on the job for long before you run out of air with a small tank.

You'll also want to figure out whether or not you're going to be running an electric or gasoline powered compressor. For indoor use, electric is a better choice since gasoline power emits toxic fumes, while larger projects that require a reliable mobile power source, especially in remote locations, will be perfectly suited for gasoline-powered compressors.

Lastly, you'll want to consider whether you're going to want to deal with an oil-lubricated or an oil-free set-up. Because most compressors have a lot of big moving parts, oil is necessary to prevent wear and tear via friction. However, for the folks that aren't hardcore DIYers or owners of an autobody shop, dealing with heavy units that require oil for operation simply isn't part of the question. Smaller, more limited purpose units do have an advantage in that regard, making them a choice selection for many general purpose users.

When taking into account these many differences, you'll notice that they affect different output metrics. For example, you'll see differences in PSI or pounds per square inch as well as horsepower output by the engine, and might notice that higher horsepower motors generally produce higher PSI. This is more important to know if you are operating heavy machinery, as larger equipment will require higher PSI.

Another metric that's helpful to know is CFM which stands for cubic feet per minute. This is probably the most important metric, because many air tools have a minimum CFM that must be met at a specific PSI before they'll even operate properly. The standard measurement for a tool is generally X CFM at 90 PSI, though it's generally a good idea to multiply that requirement by 4 and select a compressor with a CFM equal to or higher than that--this is because air tools are rated at a 25% cycle, or 15 seconds out of each minute.

Below are the average CFM requirements for the most common air tools:

- Brad Nailer .03 CFM

- Framing Nailer - 2.2 CFM

- Impact Wrench 3/8" - 2.5 - 3.5 CFM

- Impact Wrench 1/2" - 4 - 5 CFM

- Impact Wrench 1" - 10 CFM

- Ratchet 1/4" - 2.5 - 3.5 CFM

- Ratchet 3/8" - 4 - 5.5 CFM

- Drill, Reversible or Straight-Line - 3 - 6 CFM

- Chisel/Hammer - 3 - 11 CFM

- Grease Gun - 4 CFM

- Hydraulic Riveter - 4 CFM

- Mini Die Grinder - 4 - 6 CFM

- Angle Disc Grinder - 5 - 8

- Cut-off Tool - 4 - 10

- Speed Saw - 5

- Orbital Sander - 6-9

- Rotational Sander - 8 - 12.5

- Dual Sander - 11-13 CFM

- Shears - 8 - 16

- Needle Scaler - 8 - 16

Carefully check all of your requirements before you go out and invest in a fancy new air compressor and make sure that the one you select is the one that's right for you. There's no point in spending all of that money just to make a return, or worse, find out further down the road that you should have bought a compressor with a tanks a couple square inches larger. Of course, you can always rent an air compressor first to see if it's the one you need, or if you're going to need a big air compressor for a one time project.